-40%

50 CLEAR PLASTIC SELF ADHESIVE STICK SLOT HANG TABS TAG HANGERS * 16 OZ * LIMIT

$ 2.08

- Description

- Size Guide

Description

PROUDLY MADE IN USAPLEASE READ BELOW THE INFORMATION CONCERNING THE USE OF HANG TABS

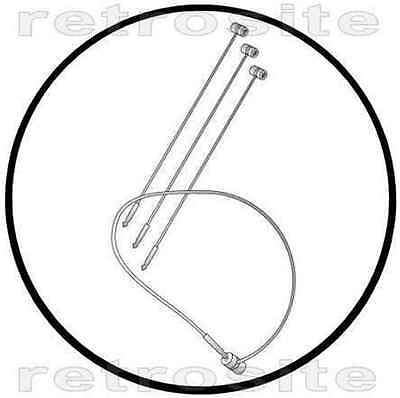

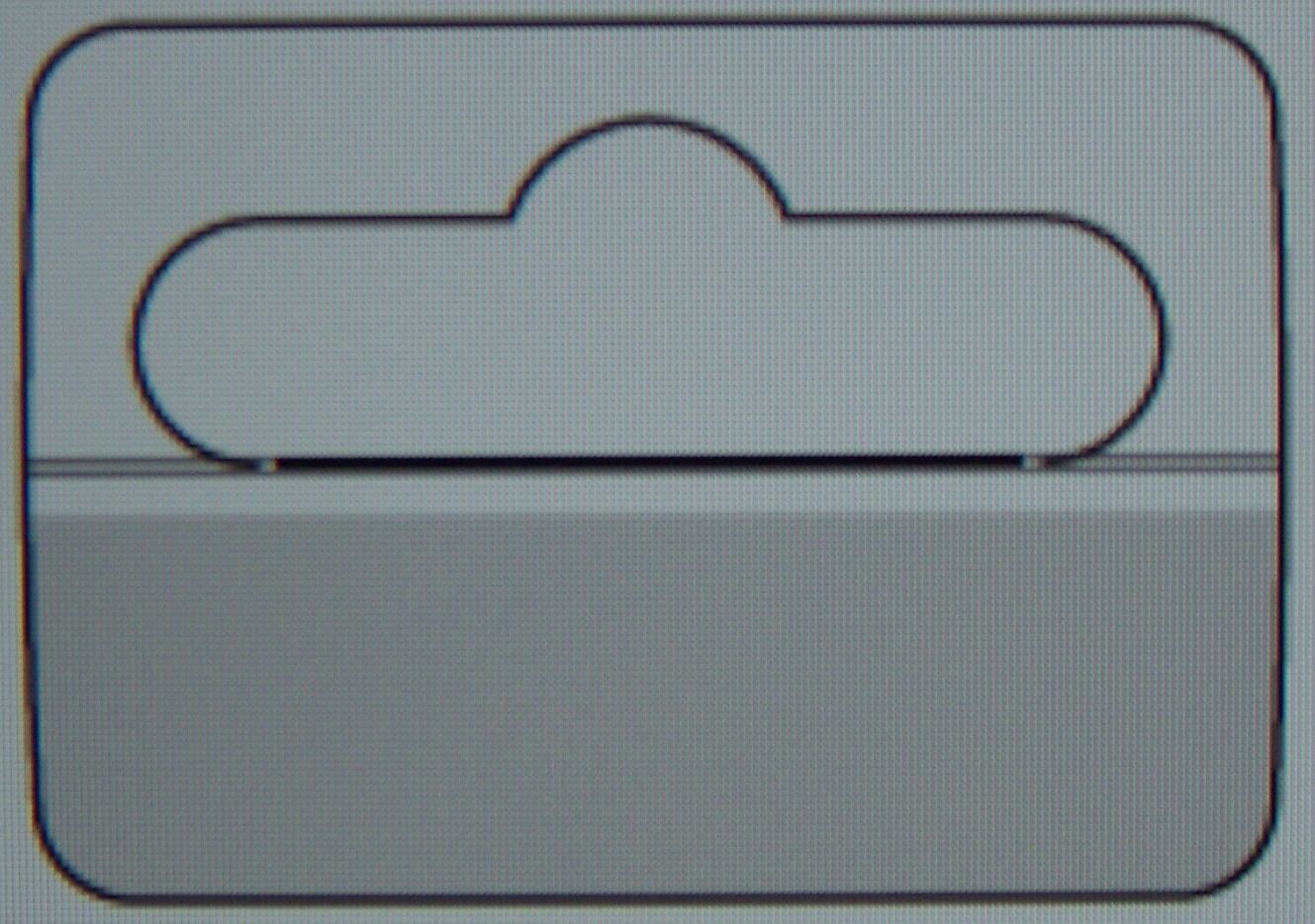

This Buy It Now listing is for 50 new clear plastic self adhesive slot style hang tabs with the following features:

·

Manufacture recommended product weight – 16 ounces / 452 grams*

·

Size – 1 1/4” H x 1 5/8” W x .015" thick

·

Size of slot – 1 3/16”

·

Size of adhesive – 1/2” H x 1 5/8” W

* The weight provided should be used as a guideline only. Performance cannot be guaranteed. You should carefully test the hang tabs for the desired performance results.

POLICIES

Thank you for viewing our auction. We will do our best to make this a smooth transaction. If you are unsure of anything in this auction, it is your responsibility to ask prior to placing a purchase. Please do not purchase until we have answered your questions. If you purchase, we expect you to go through with the sale. Remember by purchasing this item you enter a legal binding contract.

If there is any problem with your item, please contact us so we can address the problem. If you are satisfied with this transaction we would appreciate your feedback. We will leave feedback in return. By leaving feedback, it tells us that you have received your item.

WE SHIP TO USA ONLY

GENERAL INFORMATION CONCERNING HANG TABS

These hang tabs are designed to hang products on peg hooks, display strips — anywhere customers can see them. Unfortunately, sometimes, a hang tab fails to hold the product in place. Often the cause of the failure can be easily identified and corrected. When a hang tab fails, the first thing to examine is the weight and shape of the product and where, on the product, the hang tab was placed. Each style of hang tab is designed for packages of various sizes, shapes, and tested to hang a specific maximum weight. When a hang tab fails, the reason can be as simple as the wrong hang tab was selected for that particular package — the package was too heavy for that hang tab, the shape of the hang tab was wrong, or it was placed incorrectly on the package. These reasons for failure are easy to identify and correct. If it is determined that the right hang tab was used for the particular package, there are a number of other factors that can influence hang tab performance and need to be examined.

APPLYING HANG TABS

: Hang tabs should be applied on a clean, dry, contaminant-free surface.

Contamination of the adhesive area is one of most likely reasons for bad hang tab performance and can happen in a number of different ways. These include: Dust/Dirt, Silicone, Grease/Oil, Moisture, Cleaners, and Coatings.

PACKAGE SIZE AND WEIGHT

: Each hang tab has a recommended maximum display weight, when used on an optimal product/package surface. The size of the product/package can affect the tilt, or peel angle, when displayed.

SURFACE FORM

: A hang tab that is placed on a product surface that is uneven will not perform as well as a hang tab placed on a flat surface. An uneven surface will cause a reduced percentage of the adhesive to be in contact with the surface. Generally, the backside of the product/package is the best location for attaching the hang tab. “Wet-out” is used to describe the time it takes for the adhesive to completely adhere to the product/package surface. Generally, after 24 hours the adhesive will have gained maximum adhesion strength. Heat and adding pressure to the adhesive area may reduce the length of the wet-out time.

HANGING ENVIROMENT

: The optimal temperature performance range for application and display is between 60°-90° F (15°-32° C). When hang tabs are applied and displayed outside of this temperature range the adhesive will not have maximum bonding strength.

SUBSTRATES

: A hang tab is placed directly on the product or the product’s package. If it’s the product, then the hang tab needs to adhere to whatever material the product is manufactured — plastic, wood, metal, etc. If the hang tab adheres to the package, the substrate it adheres to could be plastic, paperboard, or a shrink film. Hang tabs perform differently on different substrates.

PLASTICS

: Most soft plastics, including plastics for packaging, contain materials called "plasticizers." These provide softness and flexibility to the plastic but can, over time, migrate to the surface of the material. Plasticizers can reduce the ability of an adhesive to stick when it is applied or can soften an already applied adhesive and cause it to lose its ability to support the package weight.

SHRINK FILM

: Many products that hang with a hang tab are wrapped in a shrink film. Certain shrink films work well with hang tabs and others do not. A good shrink film is one that contains little or no slip agents (waxes or plasticizers). Slip agent materials are often added to shrink films to help them run smoothly during the packaging process. Slip agents make it more difficult for the adhesive on hang tabs to bond to the shrink wrap. Often, “print grade” shrink film works well with these hang tabs.

PAPERBOARD / BOXES

: Coatings, such as ultraviolet (UV) cured varnishes are commonly used on paperboard packages and can affect hang tab adhesion. Surface coatings such as paint or ink may not be adhesive friendly or may be loosely bonded to the products so that they, not the adhesive on the hang tab, break away from the surface.

HANG TAB PEEL / DEFLECTION / DISTORTION

: Deflection or distortion are key first indicators of an over-stressed hang tab. Deflection or distortion cause greater peel stress on the adhesive and will lead to premature failure. The best way to test for peel, deflection and distortion is to apply the appropriate weight to hang tabs, place them on a peg hook and observe.

IN SUMMARY

Hang tabs should be applied to products/packaging that is clean, dry, and free from contaminates. Generally, the backside of the product/package is the best location. The optimal

temperature range is between 60° and 90° F. The adhesive should not be touched by a person’s fingers. Pressure should be applied to the backside of the hang tab at the adhesive area to activate bonding and to promote faster wet-out. No one wants a hang tab to fail. But it can happen. Many times, the initial reaction is to blame the hang tab — often, it’s not that simple. There are other factors involved that can affect how well a hang tab performs. And more often than not, these factors can be adjusted to help the hang tab succeed in hanging your product. It’s important to understand the above information to avoid hang tab failure and that I will work with you to find effective solutions to any hang tab problem.

MADE IN USA

USPS, FedEx, UPS Alert: These delivery service are experiencing unprecedented volume increases and limited employee availability due to the impacts of the pandemic. Please be patient while we are all going through the same hardship. Thank you.